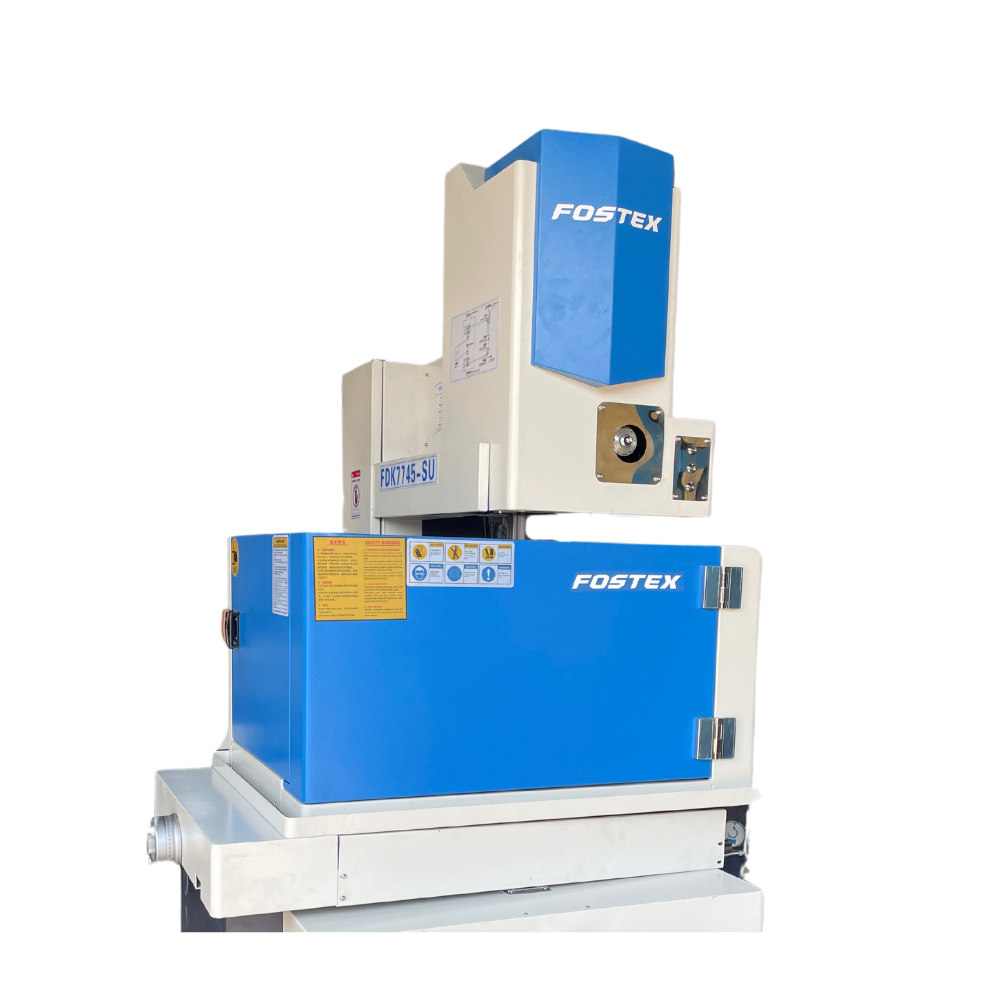

Super Series – CNC EDM Machine

Super Series

STANDARD ACCESSORIES

- CNC Multicut Controller ( easy autocad integrated)

- Dielectric System with Filtration Unit

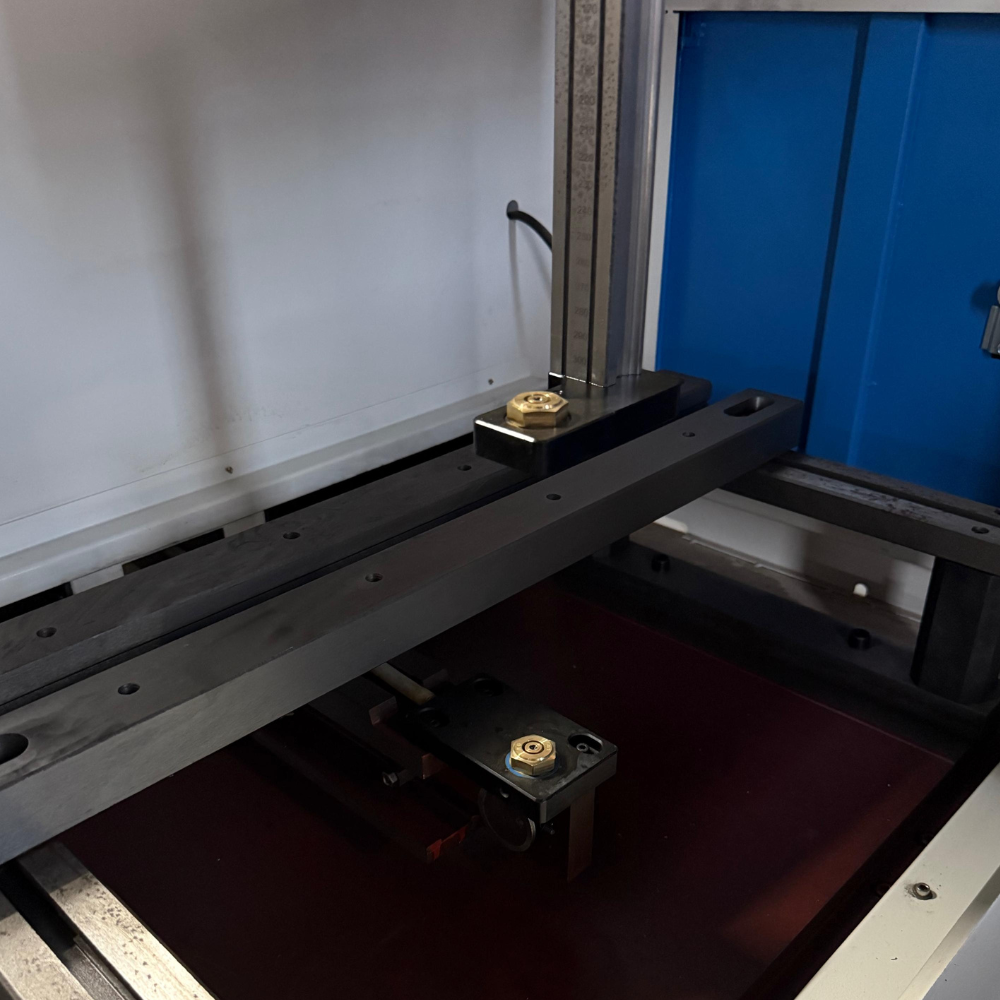

- LM Guide XYZUV

- Wire Guide

- Wire alignment tool

- Clamping tool

- 2 Axis ORO, Gel, Molly Wire

- Automatic Lubrication system

- Toolbox

- Operation Manual

OPTIONAL ACCESSORIES

- Magnetic filter

- 4th Axis Rotary Table

- Dielectric Double filter Tank

- Power Back-Up System (UPS)

Product Details:

TYPE |

FK7735-SUPER |

FK7745-SUPER |

FK7755-SUPER |

FK7763-SUPER |

Table size (mm) |

440×620 |

510×730 |

630×880 |

850X1200 |

Table travel(X/Y) (mm) |

350×450 |

450×550 |

550×630 |

630×800 |

Max.cut thickness (mm) |

300 |

300 |

400 |

400 |

Travel size(U/V) (mm) |

35×35* |

|||

Wire Dia. (mm) |

(Molybdenum wire) lj)0.10~0.30 |

|||

Wire speed (m/sec) |

12,9,7,5,2 |

|||

Cutting speed (mm’/min) |

Standard:120-140, max. cutting speed: 160-180 |

|||

Max.cutting angle |

±3°/lO0mm (15° & 30° is optional) |

|||

Process accuracy (mm) |

(Multi-cut):10xlQx30(Square) 0.010; (Single cut) 0.012 (Multi-cut)(Octagon) 0.010; (Straightness) 0.009/50mm |

|||

Roughness(Ra.um) |

(Multi-cut):Ra 1.0 (Micro-pulse power Ra 0.8) (Single cut):Ra 2.0 |

|||

Driving motor |

Stepper motor/ AC servo motor*(Optional) |

|||

Guide screw and track |

(X.Y.Z.U.V)Precision ball screw/Linear guide way |

|||

Tension system |

three stage(0/1/2)tension adjustable |

|||

Power supply |

415V/50Hz, 2.5kw |

|||

Max.workpiece weight (kg) |

400 |

500 |

800 |

1200 |

Weight (kg) |

1500 |

1700 |

2600 |

3000 |

Dimension (mm) |

1300x1200x1400 |

1600x1300x1500 |

1800x1600x1700 |

2100X1800X1800 |

Super Series CNC EDM Machine – Precision, Power & Performance

Introduction to Super Series CNC EDM Machines

The Super Series CNC EDM Machine is engineered for industries that demand high accuracy, versatility, and reliability. At CNC EDM Machine, we specialize in providing world-class CNC EDM Wire Cut Machines, CNC EDM Die Sinking Machines, and CNC EDM Spark Erosion Machines that redefine modern machining standards.

From tool & die making to aerospace, automotive, and electronics, the Super Series delivers exceptional cutting speed, smooth finishes, and maximum efficiency. With its advanced spark erosion technology and precision CNC control, it is the perfect solution for complex industrial applications.

Why Choose Super Series CNC EDM Wire Cut Machine?

The CNC EDM Wire Cut Machine in the Super Series is designed to offer superior accuracy and durability. It provides:

Micron-level precision cutting for intricate designs

Stable wire tension control for consistent performance

Energy-efficient operations reducing production costs

User-friendly CNC control for ease of programming

Smooth surface finish with minimal polishing required

Super Series CNC EDM Die Sinking Machine – High Precision for Complex Jobs

The Super Series CNC EDM Die Sinking Machine ensures efficient machining of hard metals and complex cavities. This machine is ideal for mold manufacturing and tool production. Its highlights include:

Advanced spark erosion system for deep cavity machining

High-speed, high-accuracy operations

Rugged design for long-term stability

Reduced tool wear and maintenance costs

CNC EDM Spark Erosion Machine – Technology That Delivers

The CNC EDM Spark Erosion Machine from the Super Series offers unmatched performance in shaping conductive materials. Using controlled electrical discharges, it provides:

Accurate shaping of tough metals like tungsten carbide and titanium

Minimal mechanical stress during machining

Consistent cutting quality across large production batches

Faster delivery times for precision components

Key Benefits of Super Series CNC EDM Machine

By choosing the Super Series CNC EDM Machine, industries gain:

High-precision machining with excellent surface quality

Versatility for wire cut, die sinking, and spark erosion applications

Reduced material wastage ensuring cost savings

Automation features for faster workflows

Long-lasting reliability with low maintenance requirements

Applications of Super Series CNC EDM Machines

The Super Series is widely used across:

Tool & Die Manufacturing

Aerospace and Defense Components

Automotive Industry

Medical Devices

Electronics & Micro Components

Conclusion

The Super Series CNC EDM Machine is the ultimate solution for industries requiring precision, durability, and efficiency. With advanced CNC EDM Wire Cut Machines, Die Sinking Machines, and Spark Erosion Machines, the Super Series ensures outstanding results for every application.

FAQs

The Super Series combines CNC EDM Wire Cut, CNC EDM Die Sinking, and CNC EDM Spark Erosion technologies into one high-performance range, ensuring precision and efficiency for various industries.

Yes, it can easily cut and shape materials such as titanium, tungsten carbide, and hardened steel.

Aerospace, automotive, medical device, tool & die, and electronics industries rely heavily on the Super Series CNC EDM Machines.

Absolutely. The Super Series spark erosion machines are designed to optimize power usage while delivering superior machining performance.

You can explore the full product specifications and request a quote directly at Super Series CNC EDM Machine.