What Materials Can Be Cut with Wire EDM?

A Practical Guide for Manufacturers

If you work in tool rooms, aerospace machining, die manufacturing, or high-precision engineering, you’ve probably faced this problem: a material is too hard, too delicate, or too heat-sensitive for your CNC machine. The tool breaks, the part warps, the finish is poor, or tolerances simply don’t hold. Hours of machining turn into rework, scrap, and frustration.

This is exactly why manufacturers search for materials cut by EDM to know whether their components are compatible with electrical discharge machining and whether EDM can solve the limitations of traditional cutting tools.

The truth is simple:

If the material conducts electricity, Wire EDM can cut it — cleanly, accurately, and without mechanical force.

Let’s explore how EDM works and which materials it handles best.

Understanding Electrical Discharge Machining (EDM)

EDM stands for electrical discharge machining, a non-contact cutting method. Instead of using physical tools, it removes material using controlled electrical sparks. Because there is no cutting pressure, the process is ideal for hard metals, delicate parts, and complex geometries.

This is why manufacturers who switch from milling to EDM wire cutting immediately see improvements in accuracy, finish, and part stability.

How Wire EDM Works (EDM Machine Working Principle, Simplified)

The working principle is straightforward:

- A thin brass or moly wire acts as the electrode.

- The workpiece is submerged in deionized water.

- Sparks erode the material with micron-level precision.

- The wire moves through a CNC-controlled path to form the exact shape.

Since there is no mechanical force, the process avoids deflection, tool wear, vibration, and stress on the material.

This is why Wire EDM excels where CNC milling struggles.

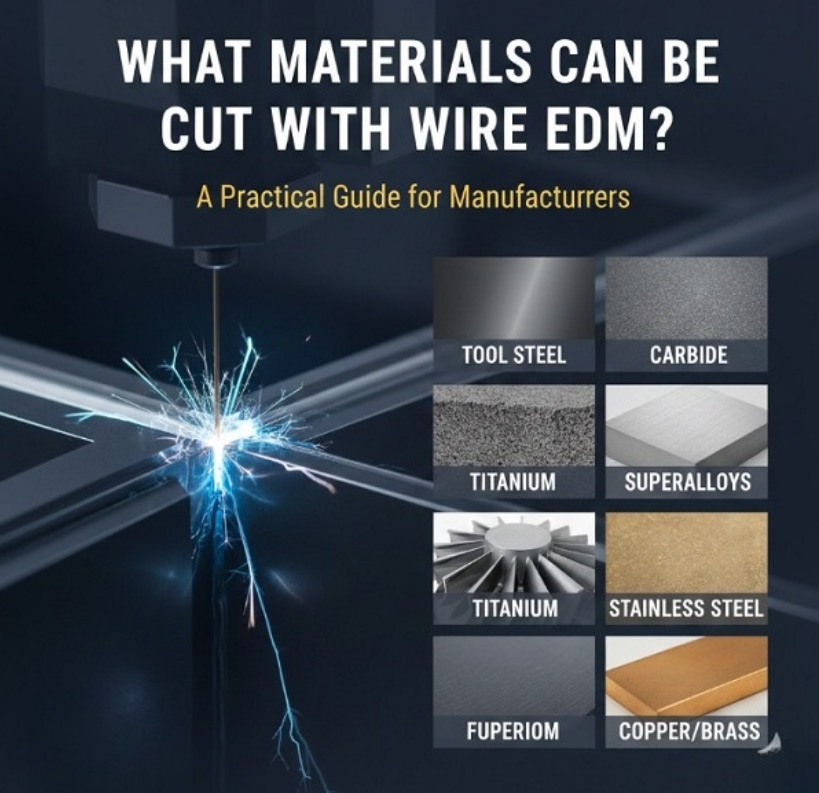

What Materials Can Be Cut with Wire EDM?

Wire EDM can cut any electrically conductive material — from soft metals to the hardest industrial alloys. Below are the most commonly machined materials, explained clearly for buyers and engineers.

Tool Steels

Tool steels are the backbone of die and mold making, but they become extremely difficult to mill once hardened.

Wire EDM cuts through them easily, even after heat treatment, without softening or changing material properties.

It maintains tight tolerances and produces clean internal corners — essential for punches, dies, and precision tooling.

Carbide and Tungsten-Based Alloys

Carbide is one of the hardest engineering materials. It breaks tools, overheats cutting inserts, and cracks under mechanical machining.

EDM is one of the few methods that can shape carbide reliably. Because EDM uses spark erosion, it avoids internal stress and delivers a burr-free finish.

Titanium

Titanium is commonly used in aerospace and medical components because of its strength and corrosion resistance.

But it is extremely heat-sensitive — a major challenge for milling.

Wire EDM solves this by cutting titanium without heat distortion or mechanical pressure.

This makes it ideal for implants, turbine parts, and high-performance components.

Nickel-Based Alloys (Inconel, Hastelloy, Monel, etc.)

These alloys are used in jet engines, turbines, and high-temperature industrial systems.

They are abrasive, tough, and destructive to cutting tools — but EDM handles them with zero tool wear.

Wire EDM provides stable dimensional accuracy even in superalloys that are nearly impossible to machine traditionally.

Stainless Steels

Stainless steels are common in aerospace, medical tools, industrial equipment, and high-precision components.

Wire EDM produces burr-free edges, clean internal geometries, and consistent finishes across all major grades.

It is excellent for thin features, slots, and intricate contours.

Copper, Brass, and Aluminum

Even softer and more conductive materials work well with EDM when precision matters.

Copper and brass are often used in electrical components, while aluminum is used in molds and prototypes.

EDM delivers a smooth finish and tight tolerances, especially for thin sections or delicate parts that can deform under a cutting tool.

Heat-Resistant Superalloys

These include:

- Inconel

- Waspaloy

- Rene alloys

They are common in aerospace and power-generation technologies.

Wire EDM can cut them cleanly without overheating, hardening, or damaging the part.

Why These Materials Work Well with EDM

All these materials share one characteristic: electrical conductivity. EDM removes metal through controlled sparks, so conductivity is essential. Beyond that, these materials benefit because EDM avoids mechanical pressure, eliminates tool wear, and maintains microscopic accuracy.

The process also handles thin sections, hard metals, and delicate profiles without causing deformation—a major advantage over conventional cutting methods.

Where EDM Cutting Is Commonly Used

Wire EDM plays an essential role in aerospace, automotive, medical device manufacturing, electronics, and the tool and die industry. Whether it’s a turbine component, a surgical tool, or a precision mold insert, manufacturers rely on EDM because it delivers consistency, repeatability, and extremely fine tolerances.

Wire EDM vs. Sinker EDM

Both processes fall under the EDM category but are used differently. Wire EDM is ideal for contour cutting, punches, profiles, and precision components. It uses a thin wire to create accurate external shapes and fine details.

Sinker EDM, on the other hand, is preferred for cavities, dies, and mold shapes where a custom electrode is plunged into the workpiece. It excels at forming deep pockets and 3D internal geometries.

Together, these methods allow manufacturers to tackle a wide range of precision machining challenges.

Choosing the Right EDM Wire Cut Machine

To cut these demanding materials reliably, the machine you choose matters. The CNC EDM Wire Cut machines from Berlin Machine are engineered for industrial stability, accuracy, and long-term performance.

Manufacturers trust Berlin Machine for consistent quality, durable construction, and precise output. With the right machine, even the toughest materials become easy to handle.

Conclusion

Understanding what materials can be cut with Wire EDM helps you choose the right method for high-precision applications. Many manufacturers regularly search for materials cut by EDM because they need a machining process that handles hard, delicate, or complex materials without compromise.

Wire EDM delivers unmatched precision across tool steels, carbide, stainless steel, superalloys, titanium, and many other conductive materials. With advanced machines from Berlin Machine, you can achieve clean, accurate, stress-free cuts every time.

FAQs: Materials Cut by Wire EDM

1. Can Wire EDM cut any type of metal?

Wire EDM can cut any electrically conductive metal, regardless of its hardness. This includes tool steel, carbide, titanium, Inconel, copper, aluminum, stainless steel, and more. If the material conducts electricity even slightly, EDM can cut it with precision.

2. Does Wire EDM change the material properties?

No. Wire EDM does not apply mechanical force or cutting pressure, so it does not cause distortion, warping, or stress. The heat-affected zone (HAZ) is extremely small, meaning hardness, strength, and metallurgical properties remain intact.

3. Is Wire EDM only for hard materials?

Not at all. While EDM is famous for cutting very hard materials like carbide and hardened steel, it is equally useful for soft and delicate materials such as copper, brass, and aluminum—especially when tight tolerances or smooth finishes are required.

4. What thickness can Wire EDM cut?

Most industrial Wire EDM machines can cut materials from 0.1 mm to 300 mm thickness, depending on wire type, machine capacity, and flushing conditions. Modern machines like those from Berlin Machine can handle thick and complex parts efficiently.

5. How accurate is Wire EDM compared to CNC milling?

Wire EDM offers micron-level accuracy, typically between ±2 to ±5 microns, which is far higher than conventional milling for intricate profiles, internal corners, thin walls, and sharp radii. This is why it is preferred for dies, punches, mold inserts, and aerospace parts.

6. What’s the difference between Wire EDM and Sinker EDM for materials?

Wire EDM is best for profiles, contours, and through-cuts in conductive materials.

Sinker EDM is used for deep cavities, mold shapes, and 3D internal forms.

Both can cut the same materials, but the application and geometry decide which process is suitable.

Leave a Reply