What Is the Cut Rate of Wire EDM?

Introduction: Why Cut Rate Matters in Wire EDM Machining

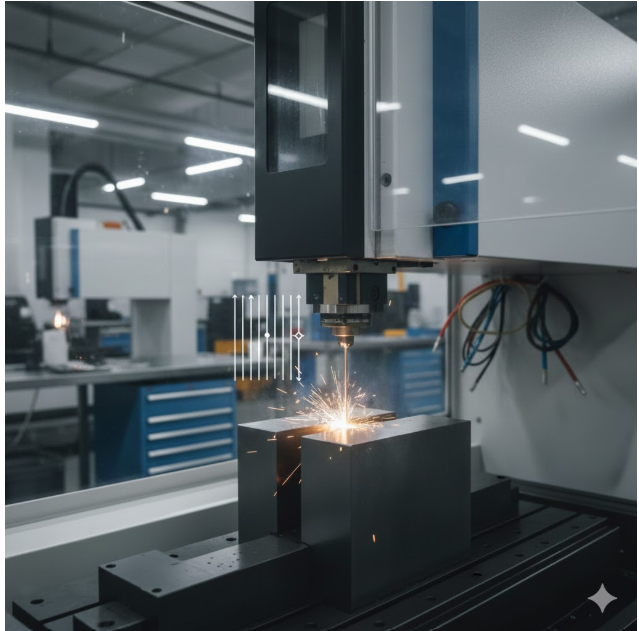

If a wire EDM job takes longer than planned, the problem usually shows up everywhere—missed delivery dates, higher part costs, and machines running overtime. Many tool rooms and die & mould shops face this daily. The root cause is often a misunderstanding of the cut rate of wire EDM. Cut rate decides how fast a wire EDM machine removes material. It directly affects production timelines, cost per job, and return on investment from the machine. Accuracy is important, but in real manufacturing, speed and consistency decide profitability. This article explains what the cut rate of wire EDM actually means, what speeds are realistic on the shop floor, and how to balance speed with accuracy without damaging parts or wasting wire.What Does “Cut Rate” Mean in Wire EDM?

Cut rate is the speed at which the EDM wire cuts through material. It is usually measured in millimeters per minute. In some cases, it is also expressed as material removal rate, which considers thickness along with speed. Unlike CNC milling, wire EDM does not use a rotating tool or mechanical force. Material is removed by controlled electrical sparks. Because of this, wire EDM cutting is slower than CNC milling but far more precise—especially for hard materials and complex shapes.Typical Cut Rate Range in Wire EDM Machines

In real production environments, wire EDM machines operate within practical speed limits. For most daily jobs, the cutting speed stays in the range of 120 to 140 mm per minute. Under ideal conditions—good conductivity, optimized settings, and moderate thickness—machines may reach 160 to 180 mm per minute. These are realistic shop-floor values. Brochure numbers often show peak performance, but running continuously at maximum speed usually leads to wire breaks, unstable cutting, and poor surface finish. Higher speed does not always mean better output.Single Cut vs Multi Cut: Impact on Cut Rate

Single cutting means the profile is cut in one pass. This is the fastest method and is widely used for general tooling and rough work. It offers good productivity but moderate accuracy and surface finish. Multi cutting, also called skim cutting, uses one rough cut followed by several finishing passes. Each additional pass improves accuracy and surface quality but reduces overall cutting speed. In practice, single cut is ideal when delivery time matters more than micron-level accuracy. Multi cut becomes necessary for molds, punches, and precision parts where fit and finish are critical.Key Factors That Affect Wire EDM Cut Rate

Workpiece Material Type

Material conductivity plays a major role in cutting speed. Tool steel cuts at stable speeds. Aluminum alloys cut faster due to higher conductivity. Carbide and exotic alloys cut slower and require careful parameter control.Material Thickness

As thickness increases, cutting speed decreases. Flushing becomes less effective in deep cuts, and wire lag increases. A thin plate can cut much faster than a thick block using the same settings.Wire Type and Diameter

Common wire sizes such as 0.20 mm and 0.25 mm are used in most applications. Thinner wire allows finer detail but slows cutting. Thicker wire improves stability and speed but limits sharp corner accuracy. Coated wires can improve speed but increase running cost.Power Supply and Pulse Control

A stable power supply ensures consistent spark energy. Modern pulse control allows faster cutting without sacrificing accuracy. Poor power control forces operators to slow down to avoid wire breaks.Servo Control and Wire Tension

Servo systems maintain the correct spark gap and wire path. Fast and stable servo response allows continuous cutting at higher speeds. Incorrect wire tension leads to vibration, breaks, and forced speed reduction.Dielectric Fluid Quality and Flushing

Clean dielectric fluid removes debris efficiently and keeps the cutting zone stable. Poor filtration reduces speed and increases wire breakage. Proper flushing is essential for maintaining consistent cut rate.Cut Rate vs Accuracy: Finding the Right Balance

Running a machine at maximum speed may look productive, but it often causes tolerance drift, rough surface finish, and frequent wire breaks. A slightly lower cut rate usually delivers better overall productivity by reducing rework and downtime. The best approach is to use higher speed for rough cutting and controlled speed for finishing. Matching cut rate to tolerance requirements leads to consistent results and lower overall cost.Wire EDM Cut Rate vs CNC Machining Speed

CNC machining is faster for roughing operations and soft materials. For simple shapes and high-volume production, CNC is often the better choice. Wire EDM is slower but superior for hard materials, complex profiles, and sharp internal corners. It delivers accuracy and repeatability that CNC machining struggles to achieve without special tooling.Applications Where Wire EDM Cut Rate Is Critical

Cut rate becomes especially important in production tooling, punch and die manufacturing, and high-mix job shops where time savings across multiple jobs add up. In aerospace and automotive tooling, speed must meet deadlines without compromising strict quality requirements.Common Misconceptions About Wire EDM Cut Rate

Many believe that higher cut rate automatically means a better machine. In reality, stability and consistency matter more than peak speed. Cut rate also changes with material and thickness—it is never fixed. Wire breaks are rarely caused by wire quality alone; power control, flushing, and servo response play a larger role.How to Choose a Wire EDM Machine Based on Cut Rate Needs

When selecting a wire EDM machine, buyers should look beyond brochure speed figures. A machine should deliver stable power, responsive servo control, effective cooling and filtration, and a controller capable of efficient cutting modes. The right machine is one that matches actual production needs, not theoretical maximum speed.

In real production environments, CNC EDM wire cut machines by Berlin Machine are designed to deliver stable cut rates through consistent power control, responsive servo systems, and effective dielectric filtration—helping shops maintain speed without sacrificing accuracy.

When selecting a wire EDM machine, buyers should look beyond brochure speed figures. A machine should deliver stable power, responsive servo control, effective cooling and filtration, and a controller capable of efficient cutting modes. The right machine is one that matches actual production needs, not theoretical maximum speed.

In real production environments, CNC EDM wire cut machines by Berlin Machine are designed to deliver stable cut rates through consistent power control, responsive servo systems, and effective dielectric filtration—helping shops maintain speed without sacrificing accuracy.

Conclusion: Setting Realistic Expectations for Wire EDM Cutting Speed

In real manufacturing, the cut rate of wire EDM typically ranges from 120 to 180 mm per minute. Pushing beyond this without proper control usually creates more problems than benefits. Consistent speed, stable cutting, and balanced accuracy matter far more than peak numbers. Choosing the right machine and settings leads to reliable output, lower cost per part, and better long-term performance.FAQs

-

What is the average cut rate of Wire EDM?

Most shops operate between 120 and 140 mm per minute for daily production work. -

Can Wire EDM cut faster without losing accuracy?

Yes, with proper power control, stable servo settings, and clean dielectric fluid. -

Does a higher cut rate increase wire consumption?

Yes. Faster cutting generally increases wire usage and overall operating cost. -

Is Wire EDM suitable for high-speed production work?

Wire EDM is best suited for low- to medium-volume precision jobs where accuracy is more critical than raw cutting speed.

Leave a Reply