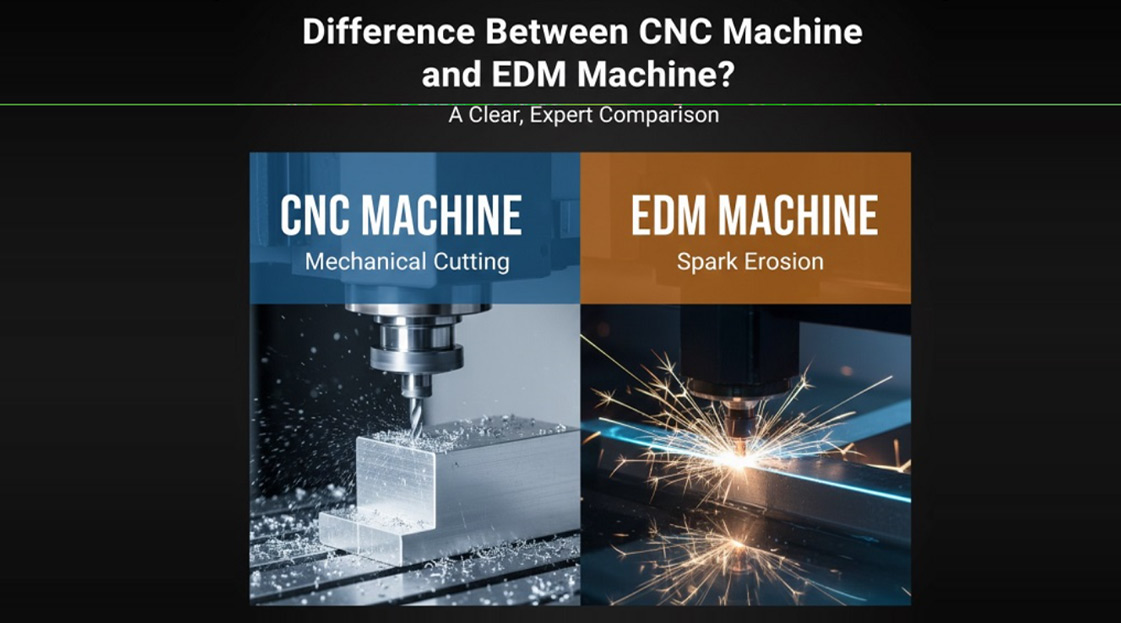

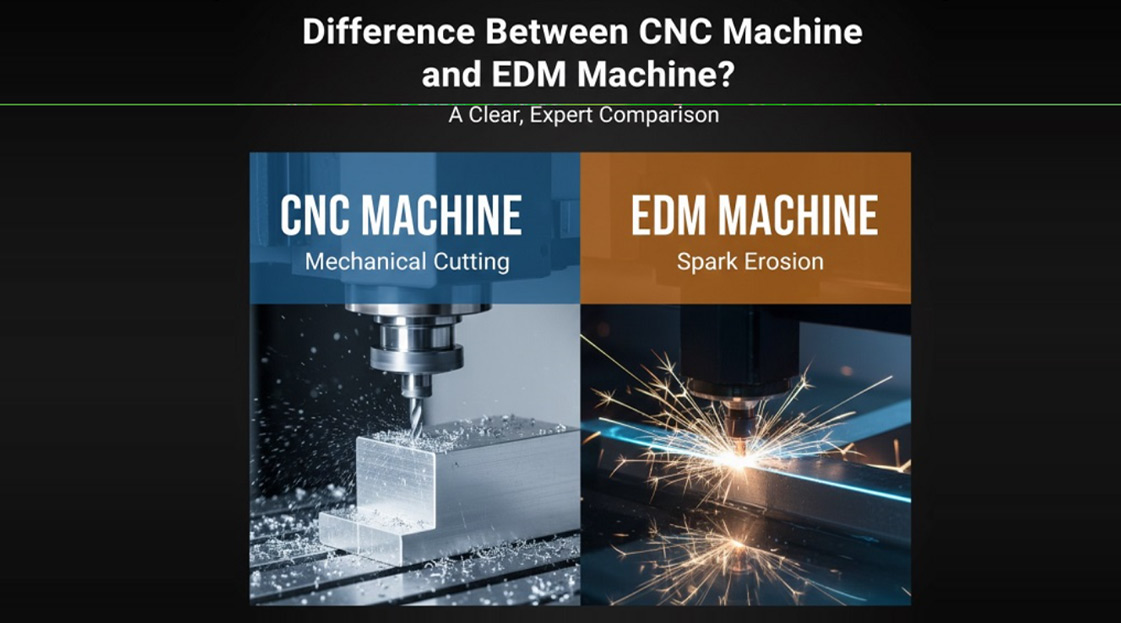

CNC vs. EDM Machine: Simple Guide to Key Differences & Uses

If you’re searching for the difference between CNC machine and EDM machine, chances are you’re stuck in the same situation many manufacturers face. You need high precision, tight tolerances, and the right machine for the job—but the more you read, the more confusing it becomes. CNC machining looks faster, EDM looks more precise, and every supplier claims their technology is better.

Before investing lakhs of rupees, you want clarity: Which technology is right for your component, tolerance, material, and production batch?

This article breaks down the differences in a simple, industry-focused language so you can confidently choose the right machine for your manufacturing needs.

What Is a CNC Machine?

A CNC (Computer Numerical Control) machine removes material through mechanical cutting. It uses rotating tools, high-speed spindles, and programmed toolpaths to shape a workpiece. The process is fast, reliable, and widely used across industries for general machining.

CNC machines include milling machines, turning centers, VMCs, and HMCs. They work exceptionally well for metals like aluminum, mild steel, and plastics, and they are the go-to choice for automotive components, fabrication parts, and day-to-day machining.

What Is an EDM Machine?

EDM (Electrical Discharge Machining) works on a completely different principle. Instead of cutting with a tool, it uses controlled electrical sparks to erode material. There is no physical contact between the wire/electrode and the workpiece.

There are two main types:

- Wire Cut EDM, used for cutting profiles and precision shapes

- Die-Sinking EDM, used for intricate cavities, mold details, and deep contours

EDM is preferred when you need extreme precision, sharp corners, thin slots, and surface finish that CNC cannot achieve—especially on hardened steels and advanced alloys.

CNC Machine vs. EDM Machine Comparison Table

| Feature |

CNC Machine |

EDM Machine |

| Working Principle |

Cutting with mechanical force |

Spark erosion without contact |

| Material Compatibility |

Soft–medium materials |

Any conductive, including hardened steel |

| Complexity Handling |

Limited for sharp corners |

Excellent for fine details |

| Accuracy |

10–50 microns |

2–5 microns |

| Surface Finish |

Tool marks present |

Very fine, smooth finish |

| Speed |

Fast |

Slower |

| Ideal For |

General machining |

Precision & mold making |

If you’re planning to invest in a

high-precision CNC EDM Wire Cut Machine, explore the Premium Servo Series by Berlin Machineries—engineered for accuracy, reliability, and long-term performance.

How They Work: CNC vs. EDM

CNC works through direct cutting. The tool rotates, applies force, and removes chips. Because material is cut mechanically, tool wear is common and surface finish depends on tool quality and feed parameters.

EDM works through spark erosion. A continuous series of electrical discharges melts material at a microscopic level. Since nothing touches the workpiece, there is no cutting force, no vibration, and almost no mechanical wear on the tool.

Material Compatibility: CNC Machine vs EDM Machine Performance on Different Materials

CNC machines have limitations when it comes to hard materials. They work best on soft and medium-hard metals, plastics, aluminum alloys, and mild steel. When the material becomes too hard or heat-treated, machining becomes slower and tool wear increases drastically.

EDM machines can cut any electrically conductive material, regardless of hardness. Hardened tool steel, carbide, tungsten, titanium, Inconel, and copper alloys—EDM cuts them all with the same precision.

Accuracy, Precision & Surface Finish

CNC can achieve good accuracy, typically in the range of 10–50 microns. However, tool marks are visible, and surface finish depends on spindle, tooling, and cutting strategy.

EDM delivers far superior precision. Wire EDM can achieve 2–5 microns with a fine finish that often doesn’t require post-processing. Multi-cut strategies can achieve surface finishes smoother than Ra 1.5.

Geometry and Design Capabilities

CNC machines struggle with tight internal corners, extremely thin slots, and complex contours. The tool diameter limits the internal radius you can achieve.

EDM easily handles sharp corners, deep profiles, intricate pockets, narrow slots, micro-features, and complex mold geometries. This makes it irreplaceable in mold and die manufacturing.

Production Speed

CNC is faster for bulk material removal and mass production. If the job requires high material removal rate, CNC is the ideal choice.

EDM cuts slower because spark erosion is a gradual process. It is used where precision is more important than speed.

Tool Wear & Maintenance

CNC machines face continuous tool wear. Cutting tools need regular replacement, and machining hard materials increases tool cost significantly.

EDM machines have almost no mechanical wear. The main consumables are EDM wire, dielectric fluid, and filters. Overall, EDM systems require less mechanical maintenance.

Cost Considerations

CNC pricing depends on machine size, tool cost, maintenance, and operator expertise. Operational costs are moderate, but tooling for hard materials can become expensive.

EDM machines have consumable costs (wire, filters, dielectric fluid) and slightly higher energy consumption. However, the precision achieved often eliminates secondary processes, making it cost-effective for complex and hardened components.

When to Choose CNC and When to Choose EDM

Choose CNC if your requirement involves:

- Bulk material removal

- General machining

- Mass production

- Components made from non-conductive materials

Choose EDM if your job demands:

- Extreme accuracy

- Hardened materials

- Mold and die components

- Sharp internal corners

- Complex profiles

- Thin slots and delicate features

Most modern machine shops use both CNC + EDM to get the best of speed and precision.

Industry Use-Cases

Automotive industries rely on CNC for general machining, engine parts, and fabrication jobs.

Mold & die shops depend heavily on EDM for precision cavities and inserts.

Aerospace, medical, and tool-room industries use EDM for high-performance alloys and tight-tolerance parts.

Which Machine Should You Invest In?

If your priority is speed, productivity, and general machining—CNC is the right choice.

If your priority is precision, hard materials, and complex mold components—EDM is unmatched.

For most advanced workshops, a combination of CNC for roughing and EDM for finishing offers the best balance of accuracy, speed, and efficiency.

Conclusion

The difference between CNC machine and EDM machine comes down to their cutting method, material capability, accuracy, and application. CNC delivers speed and productivity, while EDM delivers unmatched precision. Choosing the right technology depends on your component tolerances, material type, geometry, and production goals.

Frequently Asked Questions (FAQs)

1. What is the main difference in how CNC and EDM machines work?

The main difference is the cutting method. A CNC machine cuts material using mechanical force (a rotating tool that physically touches the part). An EDM machine removes material using controlled electrical sparks (spark erosion) without any physical contact between the tool and the workpiece.

2. Which machine is better for cutting very hard materials like hardened steel or titanium?

The EDM machine is better for very hard or heat-treated materials. It can cut any electrically conductive material regardless of its hardness with the same precision. CNC machines are best suited for softer materials like aluminum or mild steel.

3. Which machine offers better accuracy and a smoother surface finish?

The EDM machine offers significantly better accuracy (2–5 microns) and a much smoother surface finish because there are no tool marks. CNC machines typically achieve an accuracy of 10–50 microns, and the finish often has visible tool marks.

4. Which machine is faster for a typical production job?

The CNC machine is generally faster for bulk material removal and mass production because it removes material more quickly. The EDM process of spark erosion is slower, but it’s used when precision is more important than speed.

5. When should I choose a CNC machine instead of an EDM machine?

You should choose a CNC machine if your main priorities are speed, high material removal rate, and general machining of parts made from soft or medium-hard materials. It is the go-to for automotive and general fabrication jobs.

6. Do CNC and EDM machines use the same kind of cutting tools?

No, they use different methods. A CNC machine uses physical cutting tools (like end mills or inserts) which wear out and need regular replacement. An EDM machine uses an electrode or a thin wire to create sparks, meaning there is almost no mechanical wear on the “tool” itself.

If you’re searching for the difference between CNC machine and EDM machine, chances are you’re stuck in the same situation many manufacturers face. You need high precision, tight tolerances, and the right machine for the job—but the more you read, the more confusing it becomes. CNC machining looks faster, EDM looks more precise, and every supplier claims their technology is better.

Before investing lakhs of rupees, you want clarity: Which technology is right for your component, tolerance, material, and production batch?

This article breaks down the differences in a simple, industry-focused language so you can confidently choose the right machine for your manufacturing needs.

If you’re searching for the difference between CNC machine and EDM machine, chances are you’re stuck in the same situation many manufacturers face. You need high precision, tight tolerances, and the right machine for the job—but the more you read, the more confusing it becomes. CNC machining looks faster, EDM looks more precise, and every supplier claims their technology is better.

Before investing lakhs of rupees, you want clarity: Which technology is right for your component, tolerance, material, and production batch?

This article breaks down the differences in a simple, industry-focused language so you can confidently choose the right machine for your manufacturing needs.

Leave a Reply