At CNC EDM Machine India, we specialize in delivering advanced Sinker EDM (Electrical Discharge Machining) machines engineered for unmatched precision, reliability, and performance. Our CNC-controlled sinker EDMs are designed to meet the demanding requirements of industries such as mould and die making, automotive, aerospace, defence, tooling, and job shops.

Whether you’re working on complex cavities or intricate hard metal components, our machines provide high-quality finishes, optimal electrode life, and consistent repeatability, making us a trusted Sinker EDM machine manufacturer in India.

What is a Sinker EDM Machine?

A Sinker EDM machine, also known as a die-sinking EDM, uses a shaped electrode and controlled spark erosion to machine complex 3D shapes into electrically conductive materials. The process enables precise machining of hardened steel, tungsten carbide, Inconel, titanium, and more—ideal for parts that are difficult or impossible to mill using traditional methods.

Key Features of Our CNC Sinker EDM Machines

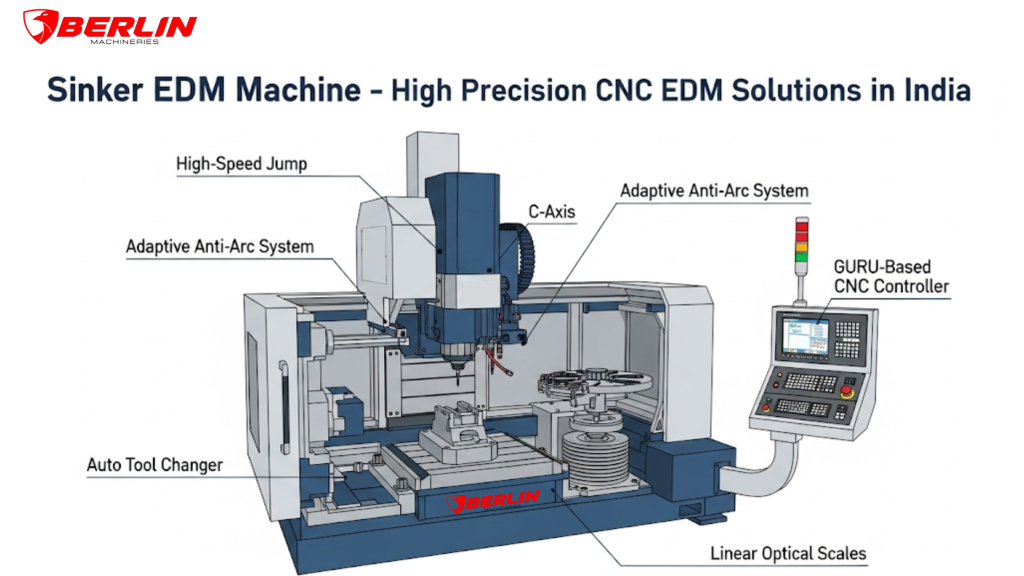

- High-Speed Jump Technology: Reduces cycle time and improves flushing efficiency with high-speed jump movement during machining. Ensures faster debris removal and better spark stability.

- Adaptive Anti-Arc System: Prevents electrode damage and ensures a stable machining environment by automatically adjusting sparking parameters during erosion.

- Intelligent CNC Controller: User-friendly touch screen interface with GURU-based programming for faster job setup, real-time monitoring, and an intuitive learning curve for operators.

- C-Axis Rotary Function (Optional): Enables indexing and rotating the electrode during machining—ideal for multi-surface cavity EDMing and complex electrode applications.

- Auto Tool Changer (Optional): Facilitates unmanned operations and productivity for longer run jobs. Perfect for mould makers and high-volume tool rooms.

- Linear Optical Scales for Precision: Ensures micron-level accuracy across X, Y, Z axes, reducing thermal drift and increasing dimensional reliability.

Model-wise Technical Specifications

| Model | Work Tank Size (mm) | XYZ Travel (mm) | Max Electrode Weight (kg) | Surface Finish (Ra µ) | Power Supply |

|---|---|---|---|---|---|

| EDM-450CNC | 800 x 600 x 350 | 400 x 300 x 250 | 75 | ≤ 0.3 | 50A Pulse Generator |

| EDM-650CNC | 1000 x 750 x 400 | 600 x 400 x 350 | 125 | ≤ 0.2 | 80A Pulse Generator |

Note: Custom configurations available on request.

Industries We Serve

- Die & Mould Industry: Cavity dies, forming dies, plastic injection moulds

- Aerospace: Complex engine components, turbine blades

- Automotive: Gear dies, transmission tooling, aluminium castings

- Defence: Precision-guided part tooling, arms components

- Medical: Surgical tool moulds, implant manufacturing

- Job Shops: General precision machining of exotic alloys

Why Choose Our Sinker EDM Machines?

- India-based support: Localized service teams across India for faster support and training

- Precision guaranteed: ±1 micron repeatability and high-quality surface finish

- Custom-built models: Machines tailored to your specific machining requirements

- After-sales training: Dedicated operator training, installation, and service support

- Cost-effective solutions: Competitive pricing with unmatched features and warranty

- Quality assurance: Machines built to ISO 9001:2015 standards with robust quality checks

Sinker EDM vs Wire EDM – Which One to Choose?

While Wire EDM is suitable for through cuts and profiles, Sinker EDM is the go-to choice for complex internal cavities, closed pockets, and 3D shapes. If your part requires no through holes, tight corner radii, or high aspect ratio cavities, Sinker EDM is the preferred solution.

Applications & Case Studies

- Case Study – Die Shop in Pune: A customer reduced machining time by 40% and electrode wear by 30% after upgrading to our EDM-650CNC with adaptive anti-arc and auto tool changer.

- Case Study – Aerospace Vendor in Bangalore: Achieved 0.2µ surface finish and 5x tool life with our high-speed jump Sinker EDM during titanium component machining.

Resources You Can Expect

- EDM Best Practices Guide

- Machining Parameter Cheat Sheet

- Productivity Enhancer Kits

- Material Erosion Recipes

- Blogs on Wire vs Sinker EDM

- Maintenance Checklists

FAQs

- What is the difference between Sinker EDM and Wire EDM?Sinker EDM is used for creating complex internal cavities and 3D shapes using a shaped electrode. It is ideal for moulds, dies, and closed pockets. Wire EDM, on the other hand, is used for cutting profiles through materials using a thin wire, and it is best suited for through cuts and contours.

- What materials can be machined using Sinker EDM?Sinker EDM can machine any electrically conductive material, including hardened tool steel, titanium, Inconel, tungsten carbide, graphite, copper, and aluminium alloys.

- What is the typical surface finish achieved with a Sinker EDM machine?With modern CNC Sinker EDM machines, you can achieve surface finishes as fine as 0.2 to 0.3 Ra µm, depending on the material, electrode, and final pass settings.

- How accurate are your CNC Sinker EDM machines?Our CNC Sinker EDM machines offer high precision with positioning accuracy and repeatability up to ±1 micron. Features like linear optical scales and closed-loop controls ensure dimensional consistency.

- Do you provide installation, training, and after-sales service in India?Yes, we offer complete support including installation, operator training, maintenance guidance, and after-sales service across India.