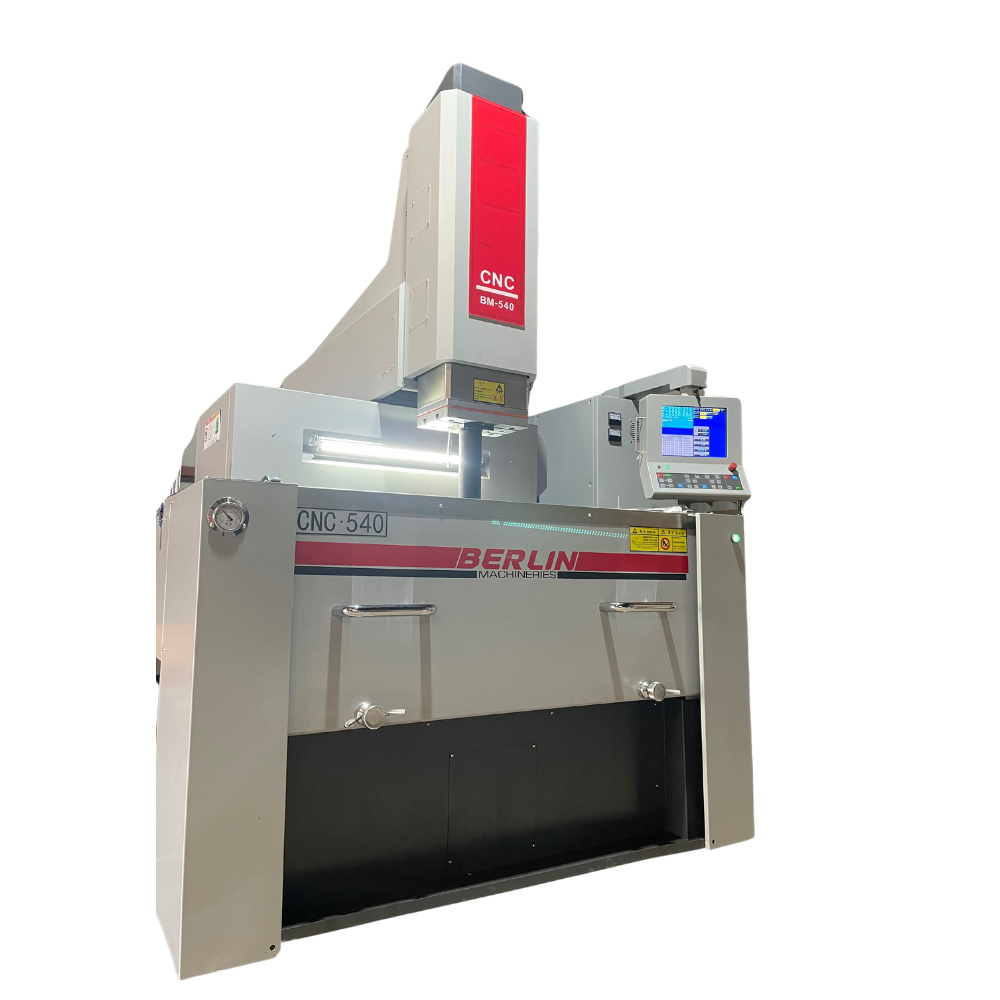

CNC EDM Die Sinking Machine for High-Precision Mold Manufacturing

Manufacturing complex molds becomes difficult when conventional machining reaches its limits. Hard materials, deep cavities, sharp corners, and fine surface details need a machining process that works without mechanical stress.

The CNC EDM Die Sinking Machine, also known as a CNC Spark Mirror EDM, is built for these challenges. It delivers high accuracy and stable performance, even when machining hardened and difficult materials.

At Berlin Machine, our CNC Spark Mirror EDM (Column Movement) machines are designed for real shop-floor use. They are built for tool rooms and manufacturing units that need repeatable accuracy and reliable long-term performance.

CNC Spark Mirror EDM (Colum Movement)

Advanced Align Techniques

- Face alignment aligns electrode with the workpiece surface

- Column center alignment find column or reference point centers

- Corner alignment aligns edges for angular machining

- Hole alignment center position for precise hole machining

- Random 3-point alignment for irregular or unique geometries

Multiple Cutting Modes

- Assist Cutting Automatically Optimize cutting from rough to finish

- manual cutting enable precise line arc thread and spiral cutting

- Multiple cutting handles batch operations with random lattice and circular patterns

What Is Die Sinking EDM Machine?

A die sinking EDM machine, also known as a CNC EDM die sinking machine, is used to create precise cavities and complex shapes by removing material through controlled electrical discharges. This die sinking process is widely used for mold and die manufacturing, especially when working with hardened or difficult-to-machine materials.

Revolutionizing Manufacturing with CNC EDM Die Sinking Machines

In the world of precision manufacturing, the CNC EDM die sinking machine stands out as a game-changer. This advanced technology combines the precision of computer numerical control (CNC) with the power of electrical discharge machining (EDM) to create intricate and highly accurate molds and dies. Whether you are in the aerospace, automotive, or electronics industry, the CNC EDM die sinking machine offers unparalleled capabilities that can significantly enhance your production processes.

Die Sinking EDM Process

In the die sinking EDM process, a shaped electrode gradually erodes material from a conductive workpiece using controlled sparks. The machining takes place in dielectric fluid, which helps control heat and remove debris. This process allows manufacturers to achieve deep cavities, sharp corners, and fine surface details that are not possible with conventional machining.

Precision and Complexity

The CNC EDM die sinking machine is designed to achieve incredibly high levels of precision. By using electrical discharges to erode material, these machines can create complex shapes and designs with tolerances as tight as a few micrometers. This level of accuracy is essential for industries where even the slightest deviation can have significant consequences. For example, in the aerospace industry, CNC EDM die sinking machines are used to manufacture turbine blades and engine components that require high precision and durability.

Applications of CNC EDM Die Sinking Machine

One of the key advantages of the CNC EDM die sinking machine is its versatility. These machines can handle a wide range of materials, including hard metals and alloys, making them ideal for various applications. In the automotive sector, CNC EDM die sinking machines are employed to create molds for injection molding and to produce critical engine parts. The electronics industry benefits from the ability to create small, intricate components for devices, ensuring high quality and reliability.

Benefits of CNC EDM Die Sinking Machines

The CNC EDM die sinking machine is not only precise but also highly efficient. The automated nature of these machines allows for consistent production without the need for constant human intervention. This results in reduced production time and increased productivity. Additionally, the use of electrical discharges minimizes tool wear, reducing maintenance costs and downtime. The combination of precision, efficiency, and reduced maintenance makes CNC EDM die sinking machines a cost-effective solution for many manufacturing processes.

Environmental and Safety Considerations

Berlin Machineries is committed to sustainability and safety. The CNC EDM die sinking machine process generates minimal waste material compared to traditional machining methods, contributing to a more sustainable manufacturing process. Moreover, the machines operate in a controlled environment, reducing the risk of accidents and ensuring a safer workplace for operators.

Choosing the Right CNC EDM Die Sinking Machine

When selecting a CNC EDM die sinking machine, it is essential to consider several factors to ensure it meets your specific needs. The type of material you will be working with, the complexity of the parts you need to produce, and the required precision levels are all critical considerations. Additionally, the machine’s brand reputation, customer support, and after-sales service should be taken into account. Berlin Machineries offers a range of CNC EDM die sinking machines, each designed to meet different manufacturing needs.

Key Points to Consider

- High Precision: Berlin Machineries’ CNC EDM die sinking machines offer unparalleled precision, with tolerances as tight as a few micrometers.

- Versatility: These machines can handle a wide range of applications, from intricate molds to high-precision components.

- Efficiency: Automated production reduces downtime and maintenance costs, enhancing overall productivity.

- Sustainability: The CNC EDM die sinking machine process generates minimal waste, contributing to a more sustainable manufacturing process.

- Safety: Controlled operation environments ensure a safer workplace for operators.

- Brand Reputation: Berlin Machineries is known for its high-quality machines and excellent customer support.

Die Sinking EDM vs Wire EDM

While both machines use electrical discharge machining, die sinking EDM and wire EDM serve different purposes. Die sinking EDM is ideal for creating closed cavities, complex mold shapes, and detailed surfaces using a custom electrode. Wire EDM, on the other hand, uses a thin wire to cut through material and is best suited for profiles and through-cuts. Choosing between die sinking EDM vs wire EDM depends on part geometry, depth, and application requirements.

Why Choose Berlin Machine for CNC EDM Die Sinking Machines?

Berlin Machine designs CNC EDM machines with a clear focus on practical manufacturing needs. Our die sinking EDM machines are built with:

- Rigid machine structures for stable machining

- Column movement design for improved alignment and accuracy

- Reliable CNC control systems for consistent operation

- Proven performance in Indian manufacturing environments

We support customers with responsive after-sales service, technical guidance, and dependable spare parts availability.

Who Should Use This CNC EDM Die Sinking Machine?

This machine is well suited for:

- Tool rooms

- Mold and die manufacturers

- Automotive and aerospace suppliers

- Precision manufacturing units

If your work involves complex cavities, fine surface details, and hardened materials, this CNC EDM die sinking machine is a strong and reliable choice.

Conclusion

The CNC EDM die sinking machine is transforming the manufacturing landscape. Its ability to deliver high precision, versatility, and efficiency makes it an invaluable asset for various industries. As technology continues to advance, Berlin Machineries will undoubtedly play an even more significant role in shaping the future of manufacturing. By investing in these advanced tools, businesses can enhance their production capabilities, improve product quality, and stay competitive in the global market.

FAQs

A CNC Spark Mirror EDM machine, also known as a die sinking EDM, is a precision machining system that removes material using controlled electrical discharges between an electrode and a conductive workpiece. It is widely used for creating complex cavities, fine surface details, and high-accuracy molds.

Column movement in a CNC Spark Mirror EDM machine provides improved rigidity, alignment accuracy, and machining stability. This design is especially beneficial for large molds and deep cavities, ensuring consistent precision throughout long machining cycles.

CNC Spark Mirror EDM machines use advanced alignment techniques such as face alignment, column center alignment, corner alignment, hole alignment, and random 3-point alignment. These methods ensure accurate electrode positioning for complex and irregular geometries.

CNC Spark Mirror EDM machines are commonly used in tool and die manufacturing, automotive mold making, aerospace component production, electronics, and precision engineering industries where high accuracy and surface finish are critical.

CNC Spark Mirror EDM machines can machine electrically conductive materials such as hardened steel, tool steel, copper, graphite, and various alloys. They are especially effective for materials that are difficult to machine using conventional methods.

Berlin Machineries’ CNC Spark Mirror EDM machines are engineered for high precision, structural stability, and long-term performance. With advanced alignment systems, multiple cutting modes, and reliable after-sales support, they are ideal for demanding mold and die manufacturing applications across India.