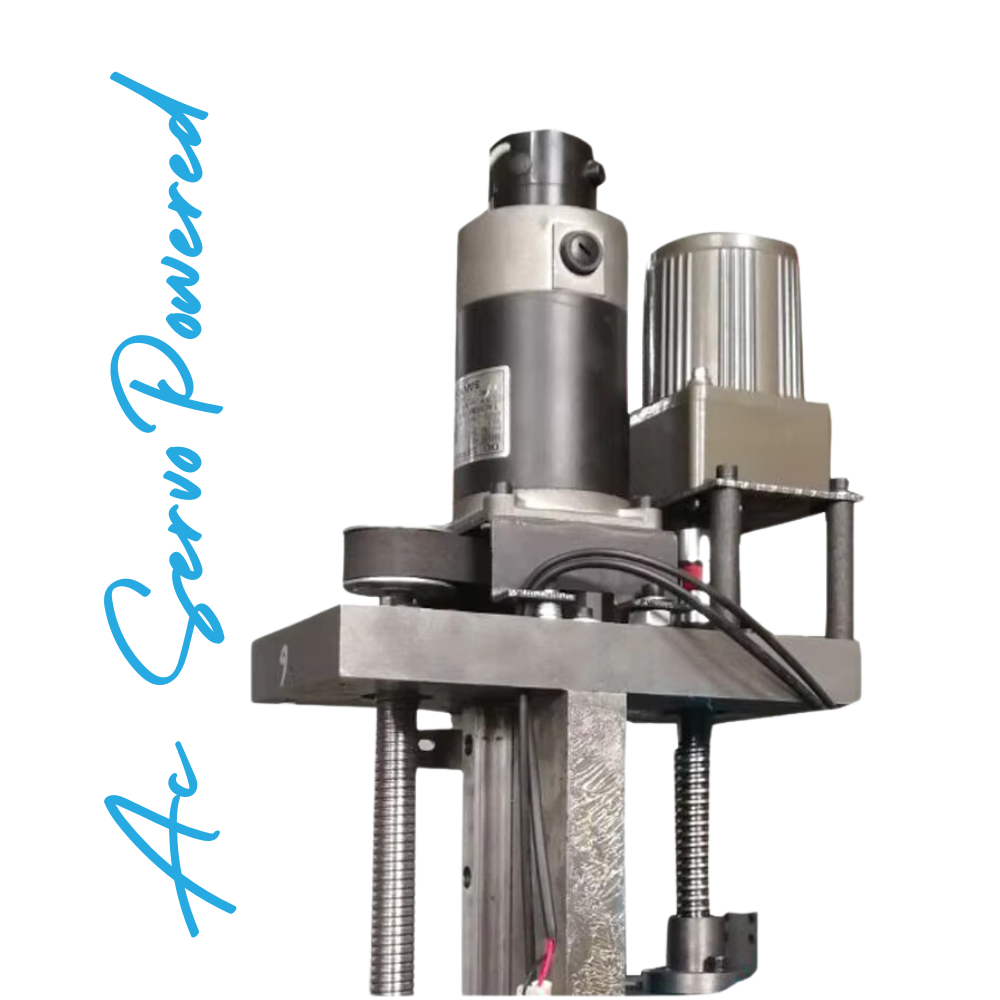

ZNC EDM Drill Machine for Precision Small Hole Drilling

Drilling small and deep holes in hardened materials is a common challenge for tool rooms and manufacturing units. Conventional drilling often leads to tool breakage, poor accuracy, and repeated rework. The ZNC EDM Drill Machine solves this problem by delivering precise, stable, and contact-free drilling, even in hard conductive materials. It helps manufacturers achieve consistent hole quality, reduce tool damage, and improve productivity in demanding drilling applications.

ZNC EDM DRILL

STANDARD ACCESSORIES

- 3-Axis ORO X,Y & Z axis

- Coolant System

- Electrode one Set

- Guide 2 Nos

- Seal

OPTIONAL ACCESSORIES

- Guide-Additional

- Seal-Additional

- Electrode-Additional

- Dielectric Double filter Tank

- Drill Chuck-Additional

Product Details:

TYPE |

FDD703.30 |

FDD703.40 |

FDD703.45 |

FDD703.55 |

FDD703.63 |

FDD703.80 |

Working Table size (mm) |

360×480 |

480*710 |

570*810 |

650*950 |

750*1140 |

980*1350 |

Stroke X-Y(mm) |

300×400 |

400*450 |

500*550 |

550*630 |

630*800 |

800*1000 |

Electrode Diameter (mm) |

<D0.3-<D3.0 |

<D0.3-<D3.0 |

<D0.3-<D3.0 |

<D0.3-<D3.0 |

<D0.3-<D3.0 |

<D0.3-<D3.0 |

Spindle Stroke W-Axis (mm) |

300 |

300 |

350 |

350 |

400 |

400 |

Working Stroke Z-Axis (mm) |

300 |

300 |

350 |

350 |

400 |

400 |

Max. Adjusting Speed of Spindle (mm/min) |

500 |

500 |

500 |

500 |

500 |

500 |

Turn head Speed (rpm) |

0-200 |

0-200 |

0-200 |

0-200 |

0-200 |

0-200 |

Distance between working Table & guider (mm) |

300 |

300 |

350 |

350 |

400 |

400 |

Power (v/Hz) |

l<D 220/3<D 415V /50Hz/ 4.0kw |

|||||

Max. Working Current (A) |

30 |

|||||

Capacity of Working Fluid (L) |

25 |

|||||

Max. Pressure of Working Fluid (MPA) |

7 |

|||||

Weight (kg) |

550 |

950 |

1100 |

1500 |

2000 |

2600 |

FAQs

A ZNC EDM Drill Machine is used for fast and accurate hole drilling in hard conductive materials. It is commonly used in tool rooms and manufacturing units for precision drilling applications.

ZNC EDM Drill Machines can drill electrically conductive materials such as hardened steel, tool steel, carbide, copper alloys, and other hard metals used in industrial manufacturing.

The ZNC EDM Drill Machine supports electrode diameters from 0.3 mm to 3.0 mm. This makes it suitable for fine and deep hole drilling applications.

Yes. The ZNC EDM Drill Machine is suitable for both tool room work and light to medium production use. It offers stable performance and consistent drilling accuracy.

Standard accessories include a coolant system, electrode set, guides, seals, and a 3-axis X, Y, and Z movement system. Optional accessories are available based on application needs.

Yes. Berlin Machine helps customers choose the correct ZNC EDM Drill model based on workpiece size, drilling depth, material type, and production requirements.